GUIDE

Benefits of Air Casters for Safe and Efficient Material Handling

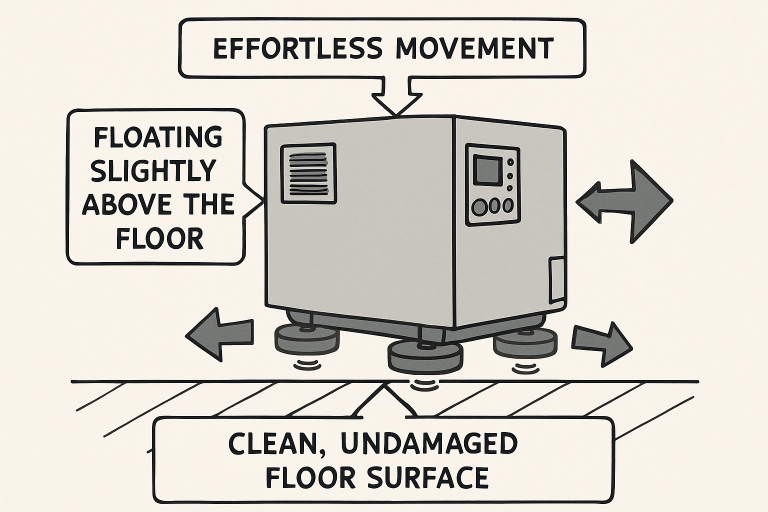

Industries are continuously seeking safer, more adaptable ways to move heavy loads, and air casters have emerged as a breakthrough solution. Unlike traditional rollers or forklifts, air casters utilize a thin layer of air to float objects, enabling effortless movement and reducing friction. This unique technology ensures precise transportation even in confined industrial settings, bringing advanced capabilities to numerous applications. For those interested in tailored solutions, such as shock absorbing casters, the advantages are even broader, addressing delicate material handling without compromising efficiency or safety.

By floating on air, heavy machinery, sensitive equipment, and multi-ton loads can be repositioned using just a fraction of the usual physical force. This not only improves ergonomics for workers but also safeguards facility floors and delicate components. With increasing demands for productivity and worker well-being, air casters stand out as a cornerstone for the future of material handling.

Implementing air caster systems revolutionizes industrial workflows in manufacturing, distribution, aerospace, and other industries. Their ability to navigate tight aisles and handle variable load shapes makes them indispensable for businesses aiming to enhance operational flexibility, lower maintenance needs, and improve employee safety.

From advanced vibration absorption to consistent weight distribution, the benefits of air casters set a new standard for reliability and efficiency in handling challenging loads. As facilities become more complex and the need for gentle handling increases, the suitability of air casters expands, including in contexts where minimizing floor wear and rapid equipment reconfiguration are vital priorities.

Enhanced Maneuverability

Air casters stand out for their ability to move massive loads in any direction with ease. Their omnidirectional movement allows for precise positioning, which is crucial in manufacturing settings with intricate machinery layouts or limited workspace. Operators can seamlessly navigate corners and tight spots, which enhances workflow efficiency and reduces the need for manual repositioning or advanced planning around obstacles. According to IndustryWeek, optimizing equipment movement can significantly reduce production downtime and enhance output reliability.

Floor Protection

Traditional wheeled systems and forklifts frequently cause scratches, dents, and other wear on facility flooring, especially under heavy loads. Air casters address this issue by distributing the load’s weight over a broad area, producing extremely low footprint pressure. This results in less wear and damage to floors, including sensitive surfaces like epoxy or tile, enabling longer intervals between costly floor repairs or replacements. Research cited by Industrial Equipment News indicates that air casters can reduce floor loading to less than 25 psi, which significantly extends floor life and reduces maintenance needs.

Improved Safety

Ensuring employee safety is essential in modern material handling operations. Air casters reduce physical strain by enabling operators to move thousands of pounds with minimal exertion, leading to fewer musculoskeletal injuries. The low profile and stable nature of air caster systems also diminishes the risk of tipping hazards and related accidents. Furthermore, air casters produce less noise and eliminate fume emissions, which promotes a safer and healthier work environment for everyone involved.

Cost-Effectiveness

Using air casters decreases overhead expenses in multiple ways. Their design lacks traditional moving parts such as axles or wheels, resulting in fewer components that can fail and minimal routine maintenance. Training staff to operate air caster systems typically takes less than half an hour, accelerating deployment and reducing the learning curve. Additionally, the ability to move equipment without breakdown and reassembly shortens downtime during facility reconfiguration, further enhancing productivity. These elements contribute to a significant return on investment over time, as highlighted by manufacturing cost analyses from Machine Design.

Versatility in Applications

Air casters cater to a wide range of industry needs. In aerospace and automotive plants, they enable the smooth transfer of relevant assemblies and tools while protecting delicate surfaces from excessive vibration. High-tech manufacturing facilities benefit from air casters’ gentle handling, especially when moving sensitive instruments or cleanroom equipment. Their adaptability to different load weights, shapes, and floor types makes air casters an essential solution for evolving industrial demands.

Specialized Uses and Expansion

Beyond industrial production lines, air casters are increasingly used in laboratories, hospitals, and logistics centers where both gentleness and precise movement are critical for safety and operational success. Their ability to absorb shocks and reduce movement-induced stress helps maintain the integrity of fragile components, electronics, and high-value assets.

Minimal Maintenance

Because air casters employ an air cushion and have no wheels or rolling elements that are subject to frequent wear, their maintenance routines are minimal. Regular inspections are limited to basic cleaning and checking for leaks. No lubricants, complex assemblies, or frequent replacements are necessary, freeing up facility resources and reducing operational interruptions.

Environmental Benefits

The use of air casters aligns with contemporary sustainability goals. Air casters not only operate without producing direct emissions, but they also do so quietly, reducing noise pollution across working environments. Their energy efficiency and reduction of wear and tear on facility floors minimize waste and the environmental impact of repairs. As standards for green manufacturing continue to rise, air casters are positioned as a responsible choice for eco-conscious operations aligning with recommendations from the Environmental Protection Agency.

Final Thoughts

Air casters represent a significant leap forward in material handling technology, setting new benchmarks for safety, floor protection, cost efficiency, and adaptability. Their ability to safely move heavy and delicate loads, while minimizing facility wear and optimizing workflow, makes them the ideal solution for manufacturers and logistics providers ready to advance their operations. By adopting air casters, industries can achieve greater productivity, reduce hidden costs, and support a safer, greener work environment for the future.

-

HOME IMPROVEMENT2 months ago

HOME IMPROVEMENT2 months agoWall Panels: Transforming Spaces with Style and Functionality

-

GUIDE2 months ago

GUIDE2 months agoBuild to Suit Opportunities Offer Turnkey Locations for Retail Business

-

HOME IMPROVEMENT2 months ago

HOME IMPROVEMENT2 months ago5 Signs It’s Time to Replace Your Windows and Doors in Orangeville

-

FAMILY2 months ago

FAMILY2 months agoFamily traditions: renewing wedding vows at Lucky Wedding Day Chapel