MORE

Details on Stainless Steel Heating Elements and Aluminum Casting

What Are Stainless Steel Heating Elements?

When it comes to pristine sword heating elements, you will want to be careful about the material you choose. Stainless sword is an extremely hard material and you may want to choose an amalgamation that will not rust. You will also want to avoid using a magnesium anode in the heating element, which can beget erosion. Stainless sword is slightly darker than other accoutrements, so you will have to be redundant careful when choosing one.

The base of a pristine sword heating element is generally made from 304 grade pristine sword and won’t rust. The slate/ watercolor heating rods are made of the loftiest grades of nickel and chromium. A good pristine sword heating element will be made of 804 grade, which is high temperature and erosion resistant. It’s also more precious than standard304/316 grade, but is much stronger and will noway rust. Stainless sword is fairly flexible. You can bend them if you need to. Some rudiments comepre-bent, but you should still look for one with a limited bond. You should also take a look at the bending compass of the pristine sword heating element. You should make sure it’s suitable for the bending shape you need. Else, you might end up with a heater that rusts. Also again, you can always replace it.

The pristine sword heating element should be made of 304 grade. It should be durable and resistant to rust. It should also be flexible enough tobend.However, you should choose a high quality pristine sword heating element, If you are a freshman. The advanced the quality, the further continuity you will have. The material itself is also easy to clean, and will repel the heat of a liquid. So, make sure you read the instructions before you buy a pristine sword heating system. The 304 grade pristine sword heating element is a good choice for utmost types of kettles. It’s1.25″in periphery and can toast up to 10 gallons of water in one and a half hours. The heating element must be plugged into an applicable thermostat and rather be submerged in water. It shouldn’t be exposed to any type of humidity, including rainwater, as it’ll affect the effectiveness of the heating device.

Stainless sword is a veritably hard material and you need to be veritably careful when choosing one. The 304 grade heating element shouldn’t be left in a dry state and should be fully submerged in water. The heater should be kept down from rust and water as it could beget seriousdamage.However, it’ll rust and might beget your wort to froth, If it’s left in a dry state. You should also keep in mind that a 316 grade heating element will last longer than a 304 grade one. While pristine sword is an extremely hard material, it’s flexible and should be used with care. You should pay special attention to the bending compass of the sword heater, because this will determine whether it’ll be safe to use. The bending compass of a 304 grade heating element is1.4 elevation, and it can be used to toast 10 gallons of water in 1 and a half hours. Still, you should make sure that the heater is fully submerged in water and that it does not come with a dry element.

Preface For Process of Aluminium Casting

The system of aluminum casting includes the addition of a range of factors to the aluminium bath. Hardeners similar as silicon, iron, bobby, magnesium, chromium, and zinc are brought to the metallic bathtub to supply it a superior and more delicate structure. These factors are delivered to the casting hogshead to minimize grain dimension and enhance extrusion parcels. This manner is honored as bones casting. This system is a complicated one, still the check end result is an aluminum product that’s fairly long lasting and erosion resistant.

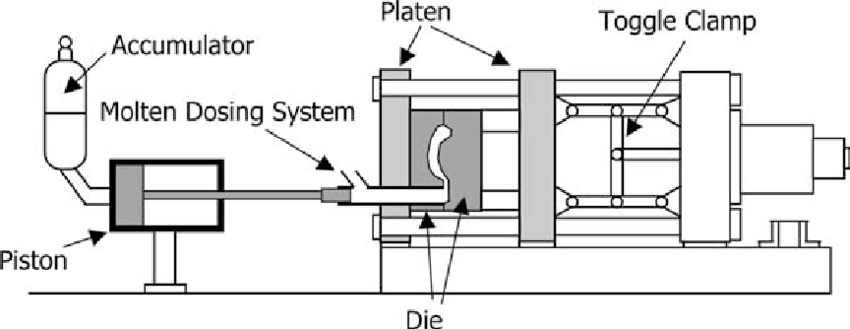

Colorful kinds of gear are accessible for aluminum casting. These machines use distinctive strategies to produce special objects. The fashion itself is complex, and there’s no single approach that will produce the great results. Some directors specialize in a unique system, still most directors give guests the desire of processes. They will also elect the bone that’s exceptional for their products. This manner is veritably time- consuming and requires exclusive chops.

The most frequent amalgamation for aluminum is 8000 series. This collection is composed of drum and bobby with small amounts of nickel. It’s unexpectedly strong, and has low tendency to warm crack. The 8000 sequence has atrocious machinability and put on resistance. Because of its low melting factor and different parcels, it’s a notorious preference for numerous diligence. these blends also have a longer lifetime. This is one of the important motives why aluminum castings are considerably used in the aerospace assiduity. In fact, solid aluminum aspects make up eighty chance of the aircraft’s structure.

The system of aluminum casting is necessary for numerous reasons. It’s a protean material, which is used in the wholeness from assembling to aerospace and vehicle factors. A right amalgamation is fairly resistant to erosion, and it’s handy to weld. It also resists heat. It’s the asked fabric for the development of aircraft. Its mechanical houses are exceedingly robust and can remaining for a veritably lengthy time. These rudiments are definitive to numerous diligence, so it’s necessary to elect the proper amalgamation for your design.

As the aluminum amalgamation is so popular, it has numerous operations. It has a magnific vary of parcels, similar as inordinate tensile electricity and erosion resistance. Its featherlight, erosion-resistant, and thermal-conductive places make it stylish for a range of operations. Its foremost end- use is the transportation assiduity. The growing recognition of motorcars has prodded the enhancement of the aluminum casting assiduity. This is due to a range of factors, similar as the growing emigration legal guidelines and purchaser demand.

The blessings of aluminum casting are multitudinous. It has an stupendous strength-to- weight rate, and is light- weight and erosion-resistant. Its beautiful aesthetic figure makes it a proper cloth for numerous artificial operations. The advantages of aluminum castings are innumerous.

-

GUIDE3 months ago

GUIDE3 months agoBenefits of Air Casters for Safe and Efficient Material Handling

-

HOME IMPROVEMENT2 months ago

HOME IMPROVEMENT2 months agoWall Panels: Transforming Spaces with Style and Functionality

-

GUIDE2 months ago

GUIDE2 months agoBuild to Suit Opportunities Offer Turnkey Locations for Retail Business

-

HOME IMPROVEMENT2 months ago

HOME IMPROVEMENT2 months ago5 Signs It’s Time to Replace Your Windows and Doors in Orangeville