MORE

How to Choose the Appropriate Zip Tie for Your Application

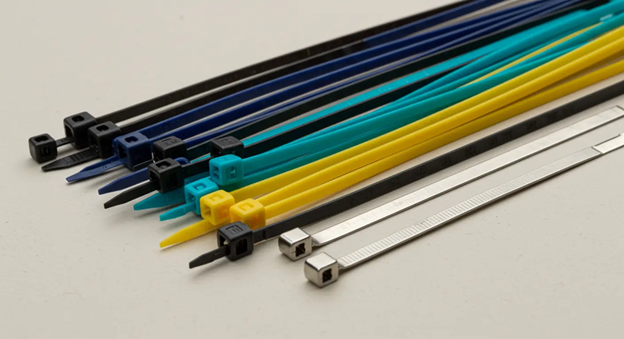

Zip ties, also known as cable ties, are important tools for organizing, securing, and bundling goods in a variety of home and commercial settings. Selecting the appropriate zip tie ensures not only the longevity of the protected items but also safety and efficiency in their use. This blog examines the many types of zip ties, highlights their significance in a variety of applications, and dives into the important factors to consider when selecting them.

Factors to Consider When Selecting the Right Zip Ties

Choosing the right zip tie includes evaluating several key factors to ensure optimal performance for your specific needs:

1. Material Composition

For specific environments, the material of a zip tie significantly influences its durability, flexibility, and suitability:

- Nylon 6/6: Nylon 6/6 zip ties are commonly used for general purposes; they offer good tensile strength and resistance to abrasion.

- UV-Resistant: These ties can handle deterioration from extended exposure to the sun, which makes them perfect for outdoor use.

- Stainless Steel: These zip ties provide high tensile strength and resistance to chemicals, heat, and UV light. These are ideal for extreme conditions.

- Metal-Detectable Nylon: This type of nylon contains metal particles that can be found using standard metal detectors; it is crucial for preventing contamination in the food and pharmaceutical industries.

2. Size and Strength

The dimensions and tensile strength of a zip tie determine the load it can handle:

- Length: Zip ties range from 4 inches to over 60 inches. Longer ties (18 inches and above) are appropriate for industrial applications needing additional tension and strength, while shorter ties (4–8 inches) are usually used for light tasks like organizing cables.

- Thickness and Width: Although they may not be as flexible, thicker and wider ties typically have a higher tensile strength. Balancing these attributes is essential for the tie’s performance.

- Strength- The maximum load that a tie can withstand before breaking is indicated by its tensile strength. Standard ties might withstand up to 50 lbs, while heavy-duty versions can handle up to 250 lbs & Extra Heavy duty ones can support upto 485 Lbs.

3. Environmental Conditions

Examine the setting in which the zip tie will be utilized:

- Temperature: Heat-resistant zip ties are crucial in high-temperature locations, such as those close to machinery or engines.

- Exposure to Elements: UV-resistant ties prevent degradation from sunlight in outdoor settings.

- Chemical Exposure: Stainless steel or specific chemical-resistant ties are advised in settings where chemicals are present.

4. Reusability

Assess the necessity of a temporary or permanent solution:

- Single-Use Ties: Standard ties are made for one-time use, providing a secure, tamper-proof solution.

- Releasable Ties: These are inexpensive for short-term uses because they have a release mechanism that permits reuse and modifications.

Various Types of Zip Ties

Understanding the different types of zip ties aids in selecting the most appropriate one for your application:

1. Standard Nylon Zip Ties

Versatile and widely used, suitable for general-purpose bundling and organizing tasks.

2. Heavy-Duty Zip Ties

This product is made for applications that require higher tensile strength, perfect for securing heavy objects or in demanding environments.

3. Releasable Zip Ties

They are suitable for temporary setups or frequent adjustments, these ties can be reused.

4. Stainless Steel Zip Ties

These zip ties are resistant to extreme temperatures, chemicals, and UV radiation, suitable for harsh environments and demanding applications.

5. Colored Zip Ties

These ties, which come in a variety of colors, aid in bundle identification and organization, improving visual management in intricate arrangements.

6. UV-Resistant Zip Ties

Made specifically to withstand prolonged exposure to sunlight, this prevents material degradation in outdoor environments.

7. Metal-Detectable Zip Ties

Incorporate metal particles, allowing detection by standard metal detectors; important in industries like food processing to prevent contamination.

8. Heat-Resistant Zip Ties

It is suitable for environments where heat exposure is frequent, such as factories or cars, because it is made to withstand high temperatures.

Importance of Using Zip Ties

Zip ties play an important role in various applications due to their versatility and efficiency:

- Organization: They help in the neat bundling of wires and cables, reducing clutter and improving safety by avoiding trip hazards.

- Security: Offer a dependable technique for securing objects, guaranteeing that parts stay in position while being transported or used.

- Efficiency: They are simple to install and remove, which saves time on initial setup and maintenance tasks.

- Cost-Effectiveness: Zip ties, which are typically inexpensive, provide an affordable option for a variety of binding and securing requirements.

- Versatility: With a variety of types available, zip ties can be used in a variety of settings, from industrial to domestic.

Selecting the right zip tie is essential for the success and safety of your project. You can ensure optimal performance by considering factors such as material composition, size and strength, environmental conditions, and the specific requirements of your application. Making an informed choice is further aided by becoming familiar with the different kinds of zip ties on the market.

-

GUIDE3 months ago

GUIDE3 months agoBenefits of Air Casters for Safe and Efficient Material Handling

-

HOME IMPROVEMENT2 months ago

HOME IMPROVEMENT2 months agoWall Panels: Transforming Spaces with Style and Functionality

-

GUIDE2 months ago

GUIDE2 months agoBuild to Suit Opportunities Offer Turnkey Locations for Retail Business

-

HOME IMPROVEMENT2 months ago

HOME IMPROVEMENT2 months ago5 Signs It’s Time to Replace Your Windows and Doors in Orangeville