TECH

PLSAR Technology to Remove Sulfur A Revolutionary Solution for Clean Energy

For the energy industry, sulfur — a well-distributed element in fossil fuels and a notorious health hazard to everything from our environment to ourselves — has been one of the biggest pain points throughout its history. When burned, fuels with sulfur in them become a major source of air pollution as they release sulfur dioxide (SO₂) into the atmosphere. Which in turn has been associated with respiratory illnesses, acid rain and the destruction of ecosystems. Therefore, it has become a high priority to clean up fuels of sulfur. PLSAR Technology to Remove Sulfur— an innovative solution to help solve this critical challenge. By applying the PLSAR to reduce sulfur, energy production could take on a form that is cleaner and more sustainable than before — transforming an industry into one with far fewer emissions worldwide.

Understanding the Basics of PLSAR Technology to Remove Sulfur

PULSAR: Plasma Sulfur Assisted Removal A highly sophisticated means, this is achieved using a plasma—which hot ionized gas that has very special properties—to combat the sulfur species in fuels much more cost-effectively. Rather than utilizing traditional sulfur removal techniques like hydrodesulfurization (HDS) that require high temperatures, pressures, and chemical reactions to extract the sulfur from fuels, PLSAR breaks down these molecules in place using plasma – a process that is more energy efficient with fewer environmental impacts.

The Growing Need for Sulfur Removal Technologies

The increasing global demand for energy, coupled with stricter environmental regulations, has led to the urgent need for technologies that can reduce the sulfur content in fuels. The harmful effects of sulfur emissions on air quality and public health are well-documented. They contribute to the formation of fine particulate matter (PM2.5), which can penetrate the respiratory system and cause severe health problems, including asthma, bronchitis, and heart disease. Moreover, sulfur emissions are a primary cause of acid rain, which damages forests, soils, and aquatic ecosystems.

The PLSAR technology to remove sulfur provides an innovative solution that aligns with the global push for cleaner energy sources. It has been developed to comply with stringent sulfur emission regulations, such as the International Maritime Organization’s (IMO) 2020 sulfur cap, which limits the sulfur content in marine fuels to 0.5% mass by mass (m/m).

How PLSAR Technology Works

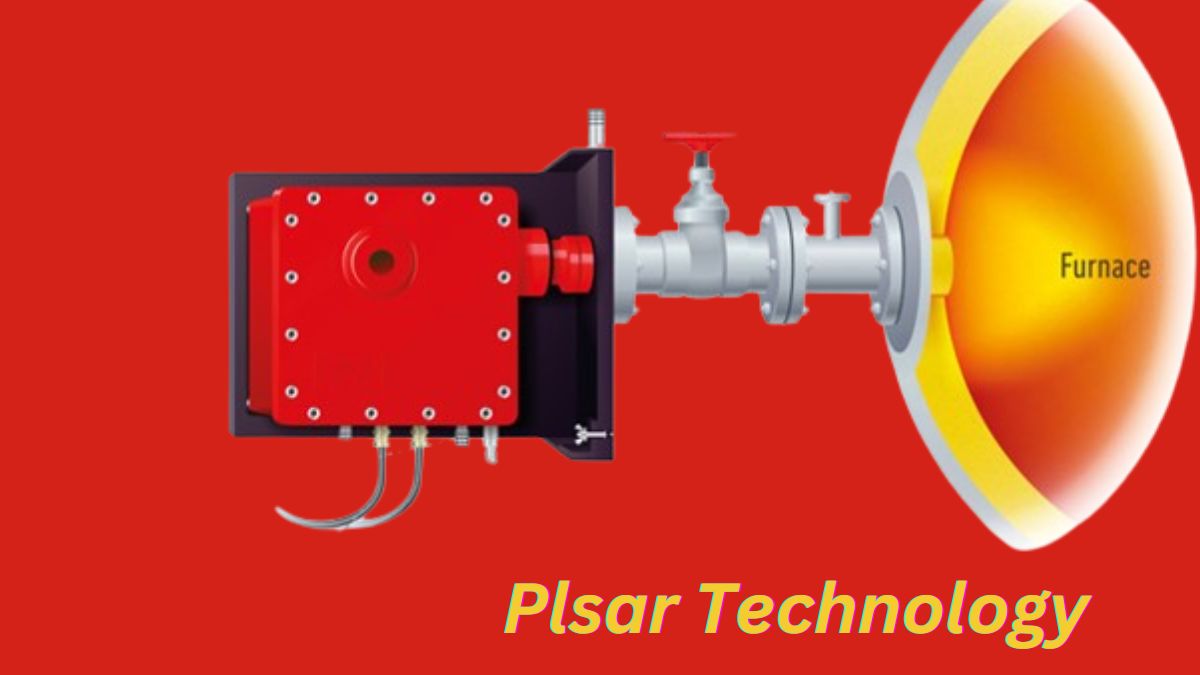

Plasma Generation

At the core of PLSAR technology is plasma generation. Plasma is created by applying an electric field to a gas, which ionizes the gas molecules, producing a highly reactive environment. In the context of sulfur removal, plasma is generated in a reactor where the fuel containing sulfur compounds is exposed to the ionized gas.

Sulfur Compound Breakdown

When sulfur-laden fuel is introduced into the plasma reactor, the high-energy plasma interacts with the sulfur compounds, breaking them down into simpler molecules. This process is achieved through a combination of thermal, chemical, and physical reactions. The plasma’s energetic particles, such as electrons and ions, collide with the sulfur molecules, causing them to decompose into harmless byproducts like sulfur dioxide, hydrogen sulfide, or elemental sulfur, which can be further processed or safely removed.

Efficient and Eco-Friendly Processing

One of the major advantages of PLSAR technology is its efficiency. Traditional desulfurization methods, like hydrodesulfurization, often require large amounts of energy and generate significant waste. In contrast, PLSAR technology operates at lower temperatures and pressures, reducing energy consumption and minimizing waste production. Furthermore, the process is highly selective, targeting only sulfur compounds while leaving other valuable components of the fuel intact.

Advantages of PLSAR Technology

Cost-Effectiveness

PLSAR technology is emerging as a cost-effective alternative to conventional sulfur removal methods. It requires less energy and fewer resources to operate, which translates to lower operational costs. Moreover, the technology can be integrated into existing refinery infrastructure, reducing the need for extensive modifications or new installations.

Environmental Benefits

The environmental benefits of PLSAR technology are substantial. By removing sulfur compounds more efficiently, it reduces the overall sulfur content in fuels, thereby decreasing sulfur dioxide emissions when these fuels are burned. This directly contributes to improved air quality and reduced acid rain, aligning with global environmental goals and policies.

Versatility and Flexibility

Unlike some sulfur removal technologies that are limited to specific types of fuels or sulfur compounds, PLSAR technology is versatile and can be applied to a wide range of fuels, including diesel, gasoline, and marine fuels. This flexibility makes it an attractive option for various industries, from transportation to power generation.

Read Also: Is There a Limit to How Much Bitcoin I Can Buy? Exploring the Boundaries of Bitcoin Purchases

Comparing PLSAR Technology to Traditional Methods

Hydrodesulfurization (HDS)

Hydrodesulfurization is the most commonly used method for sulfur removal. It involves treating fuel with hydrogen in the presence of a catalyst at high temperatures and pressures. While effective, this method is energy-intensive and costly, and it produces large amounts of carbon dioxide (CO₂) as a byproduct.

In contrast, PLSAR technology operates at lower temperatures and pressures, making it less energy-intensive. It also does not require hydrogen, which can be expensive and difficult to store and transport.

Adsorptive Desulfurization

Adsorptive desulfurization uses materials that selectively adsorb sulfur compounds from fuels. While this method can be effective, it is often limited by the capacity of the adsorbent materials, which must be regenerated or replaced frequently. PLSAR technology, on the other hand, offers continuous operation without the need for frequent regeneration or replacement of materials, making it more suitable for large-scale applications.

Applications of PLSAR Technology

Refinery Industry

In refineries, PLSAR technology can be used to desulfurize crude oil and other feedstocks, reducing the sulfur content before further processing. This enhances the overall efficiency of the refinery and ensures compliance with environmental regulations.

Marine Industry

With the implementation of the IMO 2020 sulfur cap, the marine industry has been under pressure to reduce sulfur emissions. PLSAR technology offers a viable solution for treating marine fuels, helping ship operators meet regulatory requirements without switching to more expensive low-sulfur fuels.

Automotive Sector

For the automotive sector, particularly diesel engines, PLSAR technology provides an effective way to reduce sulfur emissions, contributing to cleaner air and improved public health outcomes. The technology can be used in conjunction with other emissions control systems, such as particulate filters and catalytic converters, to achieve even greater reductions in pollutants.

The Future of PLSAR Technology in Sulfur Removal

Ongoing Research and Development

Researchers and engineers are continually working to enhance the efficiency and scalability of PLSAR technology. Advances in plasma generation and control, as well as the development of new materials for plasma reactors, are expected to further reduce costs and improve performance.

Potential for Integration with Renewable Energy

As the world moves towards renewable energy sources, there is potential for integrating PLSAR technology with renewable hydrogen production, such as that from electrolysis powered by wind or solar energy. This could create a fully sustainable system for sulfur removal, further reducing the environmental footprint of the process.

Challenges and Limitations of PLSAR Technology

While PLSAR technology holds great promise, there are still some challenges to be addressed. The initial costs of setting up plasma reactors can be high, and further research is needed to optimize the process for different types of fuels and sulfur compounds. Additionally, more real-world testing is required to fully understand the long-term performance and durability of the technology.

Conclusion

PLSAR technology to remove sulfur represents a significant step forward in the quest for cleaner energy. By offering a more efficient, cost-effective, and environmentally friendly alternative to traditional sulfur removal methods, it has the potential to transform the energy industry and contribute to global efforts to reduce emissions and protect the environment. As research and development continue, PLSAR technology could become a mainstream solution for sulfur removal, paving the way for a cleaner, greener future.

FAQs

What is PLSAR technology?

PLSAR (Plasma Sulfur Assisted Removal) technology is an advanced method for removing sulfur from fuels using plasma, an ionized gas that interacts with sulfur compounds to break them down efficiently.

How does PLSAR technology differ from traditional sulfur removal methods?

Unlike traditional methods like hydrodesulfurization, PLSAR technology operates at lower temperatures and pressures, requires no hydrogen, and produces less waste, making it more energy-efficient and environmentally friendly.

What are the benefits of using PLSAR technology in the marine industry?

PLSAR technology helps the marine industry comply with sulfur emission regulations, such as the IMO 2020 sulfur cap, by effectively reducing the sulfur content in marine fuels without the need for expensive low-sulfur alternatives.

Can PLSAR technology be used with all types of fuels?

Yes, PLSAR technology is versatile and can be applied to a wide range of fuels, including diesel, gasoline, and marine fuels, making it suitable for various industries.

What are the environmental benefits of PLSAR technology?

By removing sulfur more efficiently, PLSAR technology reduces sulfur dioxide emissions, improves air quality, reduces acid rain, and aligns with global environmental policies.

What are the prospects of PLSAR technology?

Ongoing research aims to enhance the efficiency and scalability of PLSAR technology, with potential integration into renewable energy systems for a fully sustainable sulfur removal process.

-

GUIDE3 months ago

GUIDE3 months agoBenefits of Air Casters for Safe and Efficient Material Handling

-

HOME IMPROVEMENT2 months ago

HOME IMPROVEMENT2 months agoWall Panels: Transforming Spaces with Style and Functionality

-

GUIDE2 months ago

GUIDE2 months agoBuild to Suit Opportunities Offer Turnkey Locations for Retail Business

-

HOME IMPROVEMENT2 months ago

HOME IMPROVEMENT2 months ago5 Signs It’s Time to Replace Your Windows and Doors in Orangeville