GUIDE

Zip Tie Sizes Explained: Understanding Length, Width, and Tensile Strength

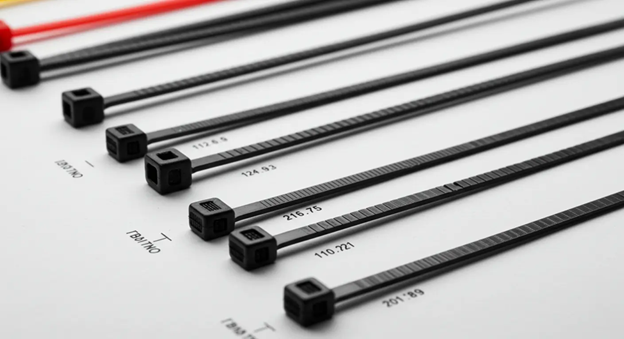

Zip ties, also known as cable ties, are important tools for various domestic and commercial uses. They are suitable for tasks ranging from simple cable management to securing heavy-duty industrial components due to their versatility stems from the array of sizes, materials, and strengths available. Choosing the right zip tie for your needs necessitates an understanding of the details of its dimensions, particularly its length, width, and tensile strength.

Length of Zip Ties

Zip ties come in a variety of lengths to accommodate different bundling requirements. Typically, standard lengths fall between 4 and 60 inches. Zip ties between 4 and 8 inches are suitable for organizing small bundles of cables or wires, ensuring a neat setup. On the other hand, longer ties—up to 60 inches long—are made for securing parts in industrial settings or bundling larger items. It’s essential to choose a length that not only fits around the items being protected but also allows for proper tensioning and fastening.

Width and Its Impact on Tensile Strength

A zip tie’s tensile strength, or the highest load it can support before breaking, is greatly influenced by its width. Zip ties are suitable for more demanding applications because of their broader ties, as they offer higher tensile strength.

Tensile Strength Considerations

When selecting a zip tie, tensile strength is important because it establishes the tie’s ability to support weight. The tensile strength required depends on the particular application.

- Light-Duty (18 lbs): Suitable for tasks like securing lightweight cables or organizing small items.

- Standard-Duty (50 lbs): Perfect for general-purpose use in homes and offices and also for bundling medium-sized cables and hoses.

- Heavy-Duty (120–250 lbs): Made for more demanding uses, like locking down large pieces of equipment or machinery in industrial settings.

- Extra Heavy-Duty (up to 250 lbs): Used in industries like aerospace, automotive, and construction where maximum strength is required.

It is crucial to remember that the zip tie’s overall tensile strength is influenced by both its width and material. For example, stainless steel zip ties, despite having similar dimensions to their nylon counterparts, provide significantly higher tensile strength and are suitable for extreme conditions.

Types of Zip Ties and Their Applications

Understanding the various types of zip ties available can help in selecting the right zip ties for your application.

- Standard nylon zip ties: Standard nylon zip ties are versatile and frequently used for various applications as they are strong and flexible.

- Heavy-Duty Zip Ties: To handle higher tensile loads, heavy-duty zip ties are designed with increased width and made from robust materials, ideal for industrial applications.

- Releasable/Reusable Zip Ties: Due to their release mechanism, releasable/reusable zip ties are ideal for circumstances where temporary bundling and adjustments are anticipated.

- Stainless Steel Zip Ties: Stainless steel zip ties can withstand extreme temperatures, chemicals, and UV radiation, which makes them suitable for harsh environments and heavy-duty applications.

- Colored Zip Ties: These ties come in different colors to help with cable management organization and coding.

- UV and Heat-Resistant Zip Ties: UV-resistant zip ties are suitable for outdoor use, they are manufactured to withstand prolonged exposure to sunlight and high temperatures.

- Metal Detectable Zip Ties: Due to the presence of metal particles that are detectable by conventional metal detectors, metal detectable zip ties are necessary to avoid contamination in the food and pharmaceutical industries.

Each type is engineered to meet specific requirements, and selecting the right type ensures durability, safety, and efficiency in your application.

Choosing the Right Size and Type

When selecting a zip tie, consider the following factors:

- Application Requirements: Ascertain whether the task is light, standard, or heavy-duty, or if it calls for particular qualities like metal detectability or UV resistance.

- Bundle Diameter: To ensure that the tie can wrap around the items with sufficient length to secure them securely, measure the circumference of the items to be bundled.

- Environmental Factors: Choose a material that is resistant to environmental factors like UV light, high temperatures, chemicals, and moisture.

- Color Coding Needs: Choose colored zip ties for easy recognition if organization and identification are priorities.

By carefully weighing these factors, you can select a zip tie that offers the best durability and performance for your specific application.

Zip ties come in various sizes, types, and strengths, making them adaptable tools for many different uses. Selecting the ideal zip tie for your requirements requires an understanding of the relationship between length, width, and tensile strength. You can make sure the chosen zip tie performs dependably and effectively by taking into account the particular needs of your task as well as the surrounding circumstances.

-

ENTERTAINMENT3 months ago

ENTERTAINMENT3 months agoBuilding Community Through Compassion: The Social Mission Behind Big Yard’s Music

-

GUIDE3 months ago

GUIDE3 months agoBenefits of Air Casters for Safe and Efficient Material Handling

-

HOME IMPROVEMENT2 months ago

HOME IMPROVEMENT2 months agoWall Panels: Transforming Spaces with Style and Functionality

-

GUIDE2 months ago

GUIDE2 months agoBuild to Suit Opportunities Offer Turnkey Locations for Retail Business